SAM Solution Coating Lab and Printed Electronics Lab

At our headquarters, we operate two labs: the Printed Electronics (SPEL) and Solution Coating.

in roll-to-roll process since its foundation and we acquired much know-how on the precision printing

and coating for the OPVs (organic photovoltaics) and printed circuits; especially slot-die coating of

ultra-thin layers and conductive metal patterns like RFID antenna. We are looking for opportunities to

expand our roll-to-roll technology for the future production processes. Currently we are conducting

three government funded research project for OPVs and printed circuits.

Our Solution Coating Lab first opened in 2016 and ran many trials such as adhesive coating and barrier coating

including laminating process. The solution line has a production scale working width of max. 1060 mm and

runs up to 1.000 m/min. Several of these trials include unique items like battery, EMI shielding and hydrophobic

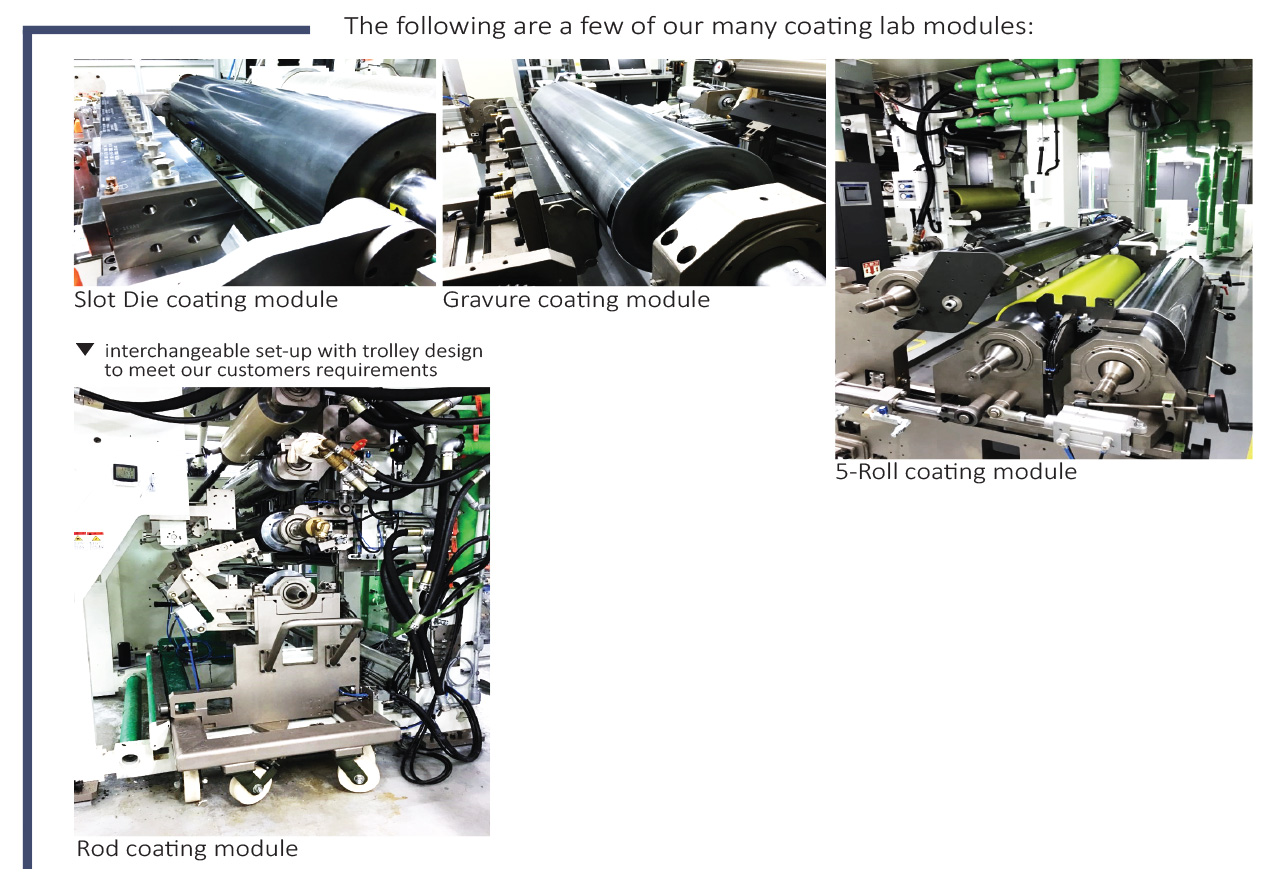

paper. All of these trials were done in our clean room facility with the various interchangeable module coating

methods.

With the roll to roll coating machines in our facility, we are able

to show all state-of-the-art coating methods presently available

on the market. So our customers are greatly benefiting from our

expertise and knowledge during trial runs with their substrates

and coating media.

However, the lines in our Labs are not only for our customers,

but also serve us to internally develop and finetune the converting

process of web like materials, like e.g. finetune new coating methods

or develop new dryer configurations. Practical experiences gained

in these test runs can be converted in theoretic calculation models,

e.g. in regards to the drying process.

But also, the machines are available for substrate suppliers, e.g. paper manufacturers to test new coatings

on their materials to develop and examine new paper grades under production conditions at high speeds

with the solution line. The trials done in small scale on our 300mm wide line can be transferred without

any issues to the 1.060mm wide production line.

Please contact us to schedule your next trial!

Website: http://www.sungan.net/en/?c=rnd&s=1

Contact: tech@sungan.net