SAM North America Extrusion Coating Lab

Did you know the SAM North America Extrusion Coating Lab opened in 2014 and we ran our 1st lab trial in May of that year? We have since ran almost 100 lab trials and have served 50 converting customers in that short timeframe.

At Sam North America we listen to our customers and try to better serve their process requirements. In the past year we made the following lab improvements.

The unwind and rewind motors and drives were increased to run at higher tension levels.

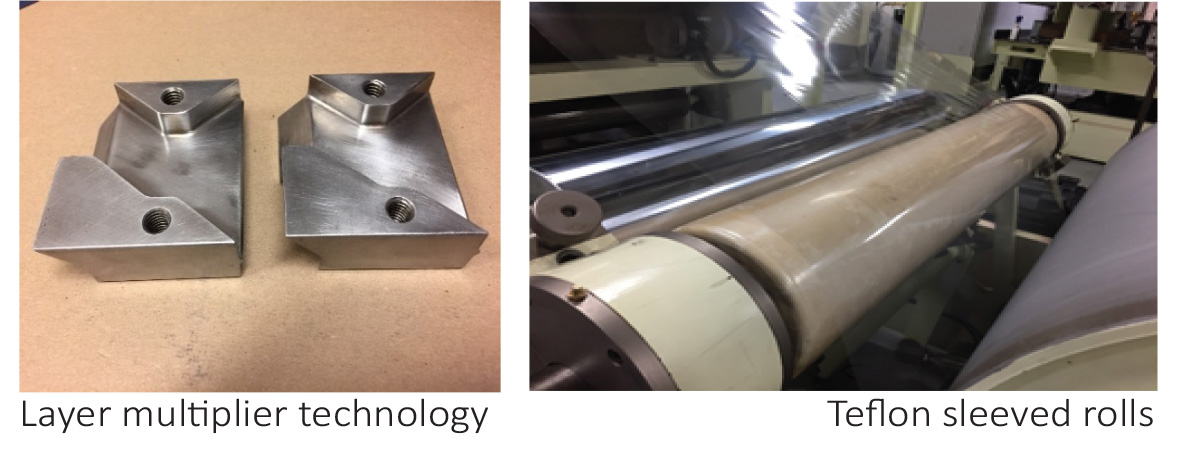

We added teflon sleeved backing rolls on our laminator which reduces changeover time while running trials.

Special covering on our Idler rolls have been added to allow us to run light films without scratching and slipping.

A new rotary mixer provides the ability to quickly blend different resins offline.

Our modified smoke hoods decrease the minimum air gap and provide a wider range of possible die air gap and die to chill roll angles.

We increased our total selector pins for the 5-layer feed block which will allow 11 available feedblock pins to provide AAAAA, AAABC, AAABB, AACBB, ACBCA, BBBBB, BAAAB, BAAAC, CCAAA, CAAAC, CABAC configurations.

Edge encapsulation hardware has been added and allows us to run and develop process procedures for customers processing low melt strength polymers. Converters who cast PET film will have special interest.

We witnessed a large increase of interest for customers wanting to run up to 14-layer polymer coating through our 5-layer feedblock and layer multiplier technology.

A static transfer system has been added to the rewind which eliminates tape transfers.

We are now booking lab trials into the 2018 calendar year so please visit our SAM North America web site to schedule your next trial